Andson Biotech

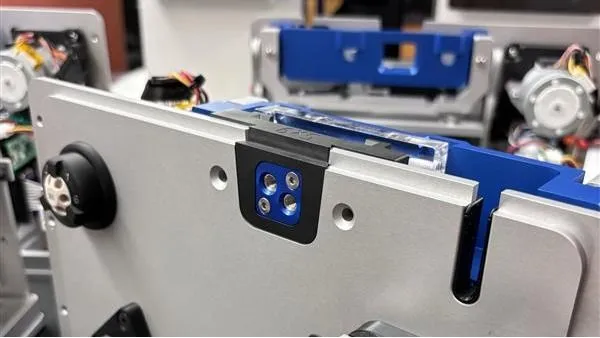

I was the first software or electrical engineer at Andson Biotech (YC W22 - website, linkedin). I built the entire tech stack of the Dynachip X1 mass spectrometry sample filtration device from scratch. This included a Python backend, React frontend, and embedded C++, as well as custom PCBs, and various cloud infra. I did this as a one-man team. My time was split ~80/20 software/electrical.

(All the information in this post was approved for release by Andson Biotech)

I worked at Andson from May 2024 - June 2025 and it was a ton of fun! It was my first work experience on a consumer product, and my first time building the electronics and software of something with so many moving parts (literally and figuratively). The end result is (as of Nov 2025) a robust, smart machine and a quickly growing company.

As well as the on-device software, I developed a shared database for usage metrics (Postgres) that syncs with on-device databases (SQLite) for offline use. I also created various visualization and fleet tracking frontends, an OTA update system, a tool to write RFID to the device’s consumables, and various smaller internal tools.

One of the most difficult and fun parts of my time at Andson was the device’s fluids control loop. For proper system function, it’s important that two flow paths with orders of magnitude different flowrates are both precisely measured and controlled. Additional constraints make this quite the nasty controls problem. Using various sensors (pressure and flowrate), I was able to develop a precise and robust controller that is able to maintain stability (and thus system functionality) under widely varying conditions.

Another highlight was chasing down and eventually resolving a core electrical technical challenge of the technology, which manifested as a sporadic near-complete failure of the device’s filtration (its core purpose). After months of taking notes and trying to achieve reproducibility, I implemented a solution on PCB which stood the test of time.

I interfaced extensively with Andson’s mechanical engineers and scientists. This (as well as being a one-man team) helped my communication skills a lot; I was forced to translate my programming and electrical knowledge into actionable information for people not familiar with software or circuits. It was also fun to be one of few non-PhD technical employees - I learned a lot through osmosis (and also learned about osmosis).

During my time at Andson, I realized my passion and natural inclination towards software. Once a stable product was delivered, I decided to pursue other opportunies where I could better grow and apply my software skills.